What is the typical workflow to produce an injection mold with subgates using MaxxMacro setups?

The typical workflow follows sequential stages that combine CNC machining and EDM with modular MaxxMacro workholding to ensure repeatability and fast changeovers. A concise workflow is:

- Mount the workpiece on a MaxxMacro Performance Pallet for secure, repeatable transfers between machines.

- Rough mill cavities and runners on a 5-axis machine using a MaxxMagnum manual chuck to remove bulk material quickly.

- Machine electrodes on a 3-axis electrode center using MaxxMacro multi-chucks or rail chucks for long, automated runs.

- Finish cavities and complex features with EDM while the part is held in a low-profile MaxxMacro chuck for stability.

- Machine the subgate (trim and angle) using a MaxxMacro adapter/angle chuck to achieve the correct gate geometry and surface finish.

Using modular pallets and chucks allows the workpiece or pallet to move from machine to machine without re-fixturing, reducing setup time and preserving alignment tolerances across operations.

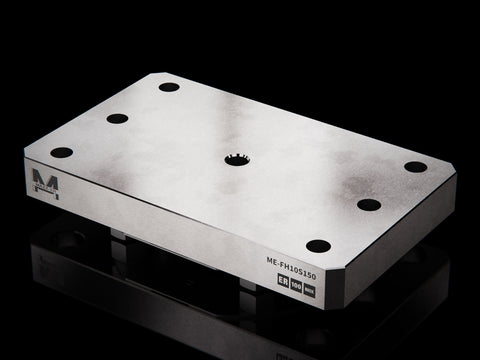

Which MaxxMacro product do you recommend for mounting and transferring workpieces?

We recommend the MaxxMacro 70 Stainless Performance Rust Proof Pallet with 6mm Dowels (MM-PA70W006). Machined from a solid piece of 440C stainless steel, this performance pallet is corrosion resistant, dimensionally stable, and designed for multiple machine transfers — you can move the part from milling to EDM to inspection without re-clamping, which saves time and reduces error accumulation.

What setup should I use for rough milling of mold cavities and runners?

For rough milling on a 5-axis machine we recommend a MaxxMagnum manual chuck such as the MaxxMagnum 680.24RS Manual Chuck Low Profile WEDM Rust Proof (MM-MGMGS000). This chuck supports Macro 54 and Macro 70 fixtures and provides a robust interface for heavy material removal. In roughing you remove bulk material and establish runner geometry so the subsequent EDM burn is faster and focused on finishing critical surfaces and tight tolerances.

How should electrodes be produced for subgate and cavity finishing?

Electrodes are best produced on a dedicated machining center using MaxxMacro multi-chucks or rail chucks to maximize throughput. For long runs use the MaxxMacro 54 Multi 3 Quick Chuck Precision Rail (MM-QCR1S003). For holding round stock for subgate electrodes, the MaxxMacro 54 Stainless ER Collet Chuck ER20 (MM-CC54S020) is an excellent choice. MaxxMacro also offers a wide variety of holders (brass, stainless, aluminum) and pallet options so you can match material and automation needs.

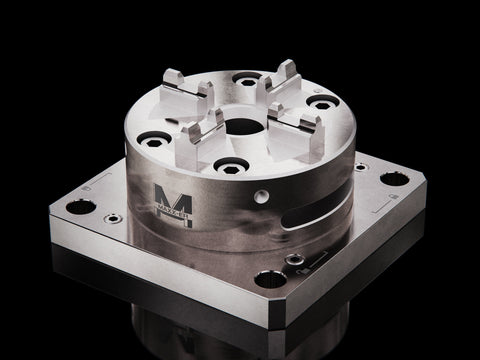

Why use EDM for molding cavities when CNC milling is available?

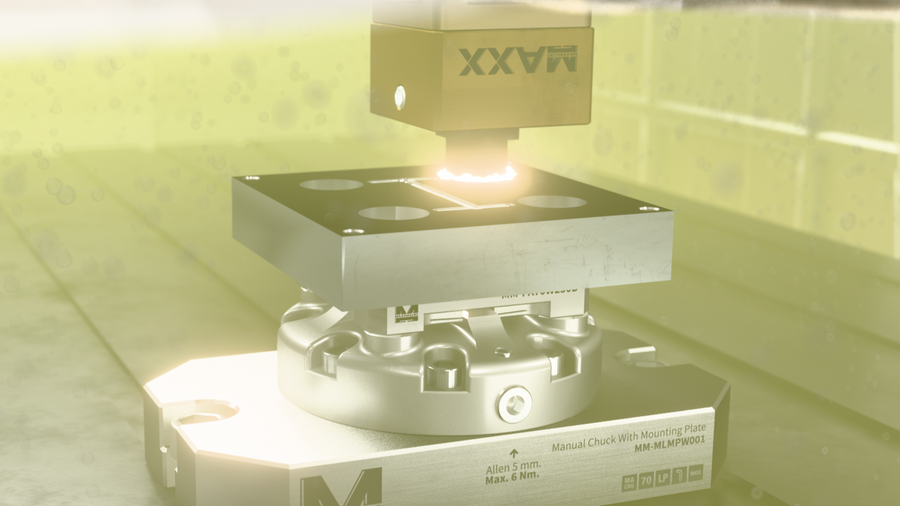

EDM (Electrical Discharge Machining) is preferred for finishing complex cavity shapes, tight tolerances, and superior surface finish. When cavities are pre-roughed on a 5-axis mill, EDM burn time is reduced and accuracy increases — EDM produces sharp corners, thin ribs, and fine details that are difficult or impossible with conventional milling. Use a low-profile MaxxMacro chuck such as the MaxxMacro 70 Low Profile Manual Chuck with Mounting Plate (MM-MLMPW001) to securely hold the pallet or mounting plate during EDM for the best results.

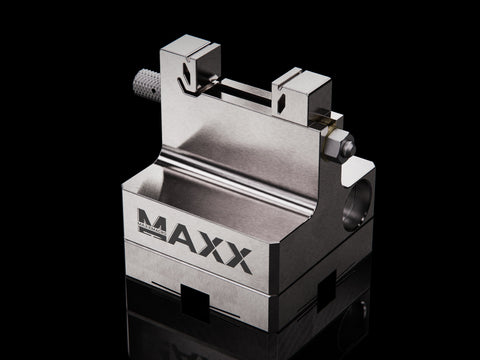

How do I machine and finish subgates, and which adapter helps set the gate angle?

Subgates require precise orientation and clean trimming to provide the part with optimal cosmetic and functional results while minimizing vestige. Use the MaxxMacro 54 Manual QuickChuck Variable Angle Adapter WEDM Rust Proof (MM-QCVAW001) to set the correct angle for burning or trimming the subgate. The variable-angle adapter gives you the ability to position the electrode or tool at the optimal angle to produce a clean subgate geometry that is easy to deflash and leaves a small vestige.

What are the advantages of using subgates in injection molds?

Subgates (also called submarine gates) are commonly used in injection molding because they combine process and part benefits:

- Improved aesthetics: Subgates leave a small, usually hidden vestige that’s easy to trim and often located in non-visible areas.

- Automatic degating: Parts often separate from the runner automatically during ejection, reducing manual labor.

- Reduced gate marks: The gate location and geometry minimize stress and visible blemishes on the molded part.

- Better flow and pressure control: Subgates allow for precise gate cross-section control which helps balance fill and reduce flow lines and burn marks.

- Shorter cycle times: Proper subgate design can reduce hold/pack times and improve cooling efficiency, especially in multi-cavity tools.

For mold makers, subgates require accurate machining and finish to perform reliably — this is where EDM plus precise MaxxMacro fixturing deliver consistent, repeatable results.

How do MaxxMacro setups improve repeatability and production efficiency?

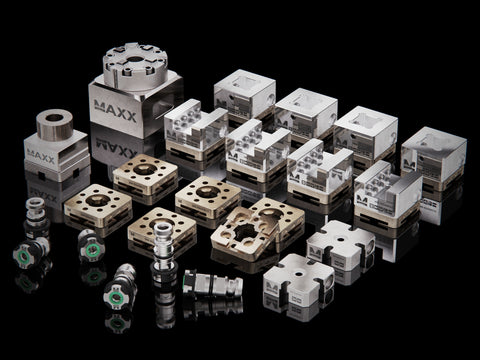

MaxxMacro systems (pallets, chucks, rail chucks, and adapters) are designed for repeatable interfaces and fast changeovers. Key efficiency points include:

- Single-mount transfer: Mount once on a performance pallet (e.g., MM-PA70W006) and move the pallet between machines without re-clamping.

- Modular compatibility: Standardized Macro 54 / Macro 70 interfaces let you share fixtures across mills, EDMs, and inspection systems.

- Reduced setup time: Quick chucks and rail systems enable batch electrode machining and fast pallet swaps.

- Higher uptime: Durable stainless and rust-proof components reduce maintenance and preserve alignment over many cycles.

Can you summarize recommended MaxxMacro items used in this guide?

Yes — the key components referenced in this process are:

- MaxxMacro 70 Stainless Performance Rust Proof Pallet (MM-PA70W006) — pallet for transfers

- MaxxMagnum 680.24RS Manual Chuck Low Profile WEDM Rust Proof (MM-MGMGS000) — 5-axis rough milling chuck

- MaxxMacro 54 Multi 3 Quick Chuck Precision Rail (MM-QCR1S003) — electrode rail chuck

- MaxxMacro 54 Stainless ER Collet Chuck ER20 (MM-CC54S020) — round stock electrode holding

- MaxxMacro 70 Low Profile Manual Chuck with Mounting Plate (MM-MLMPW001) — EDM chuck

- MaxxMacro 54 Manual QuickChuck Variable Angle Adapter (MM-QCVAW001) — subgate angle adapter

What best practices should mold makers follow when using subgates with MaxxMacro systems?

Follow these recommendations to maximize success:

- Always use a performance pallet for multi-machine workflows to eliminate repeated fixturing errors.

- Rough cavities first (5-axis) to minimize EDM burn time; then finish with EDM for tolerance and surface quality.

- Standardize electrode holders and chucks so tools and electrodes can be produced in automated batches.

- Validate subgate geometry with a prototype run and inspect the vestige location to ensure cosmetic requirements are met.

- Document and label pallet orientations (dowel pins, datum faces) so operators can swap pallets without ambiguity.