Categories

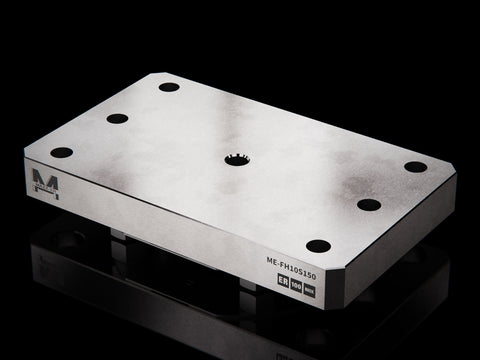

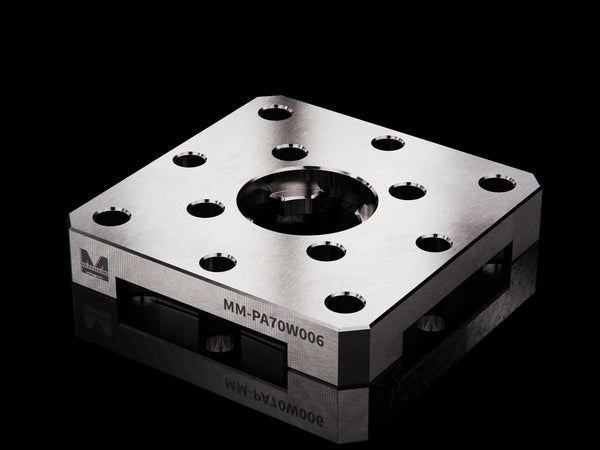

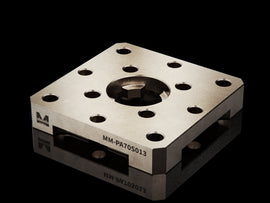

MaxxMacro 70 Stainless Performance Pallet with 6mm Dowels WEDM Rust Proof

$158.00

Regular price

$158.00

AUD

Sale

- Product Details

- Shipping & Returns

- FAQ

- Related News

- Plastic Injection Mold Production with Subgates: Step-by-Step Using MaxxMacro Workholding Systems

- MaxxMacro Premium Pallets. How do they look after 2800 cycles?

- The 2024 SKU Update for Enhanced Clarity and Compatibility

-

Maxx-Features

MaxxMacroMaxxMacro 70Corrosion ResistantSuited for Submerged

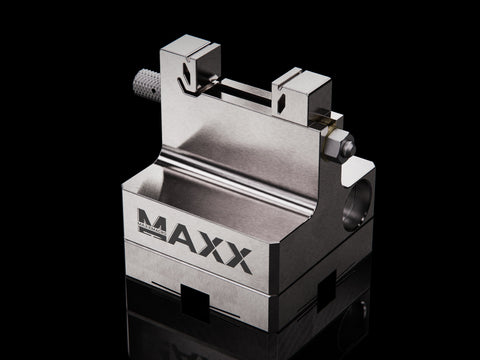

MaxxMacro 70 Stainless Performance Rust Proof Pallet with 6mm Dowels comes fully assembled and ready to use. This product is 100% cross-compatible with the System 3R Macro OEM system. Machined from solid Stainless 440c block, performance pallet with 6mm finished dowels.

MaxxDesign Exclusive Features:

- Machined from solid 440C stainless steel for maximum strength and corrosion resistance

- Includes four finished 6mm dowel holes

Product Information:

MaxxMacro 70 Stainless Performance Rust Proof Pallet with 6mm Dowels is not a cast pallet—it’s precision-machined from a solid block of 440C stainless steel, offering the highest performance, quality, and rigidity available. Its corrosion-resistant construction makes it ideal for even the most demanding machining environments, with no risk of flaking or peeling as seen in plated alternatives. This ensures long-lasting performance and reliability. As part of the extensive MaxxMacro product range, this pallet performs exceptionally well even as a standalone fixture. It allows for easy workpiece mounting with screws and provides an outstanding direct repeatability of 0.002 mm, fully compatible with the System 3R Macro interface.

Product Details

| Product Name | MaxxMacro 70 Stainless Performance Pallet with 6mm Dowels WEDM Rust Proof |

| SKU [Old SKU] | MM-PA70W006 [MX-70PALD6MM] |

| System | MaxxMacro (System 3R 100% Cross-Compatible) |

| Cross-Compatible | 3R-601.7-N, 3R-601.7-P, 3R-601.7E-P |

| System Repeatability | 0.002mm |

| Material | Stainless 440C |

| Weight | 0.3 kg | 0.66 lb |

Returns Policy

You may return most new, unused items within 30 days of delivery for a refund. There is a 20% restock fee if the item is returned due to customer error. The customer is responsible for the return shipping costs if the return is a result of your error (Not if received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the 'Complete Orders' link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

International shipments it is the customers responsibility to determine if there are any taxes or import duties payable and to make arrangements to clear and pay these fees if applicable.Plastic Injection Mold Production with Subgates: Step-by-Step Using MaxxMacro Workholding Systems

Published on: Oct 14, 2025

What is the typical workflow to produce an injection mold with subgates using MaxxMacro setups?

The typical workflow follows sequential stages that combine CNC machining and EDM with modular MaxxMacro workholding to ensure repeatability and fast changeovers. A concise workflow is:

- Mount the workpiece on a MaxxMacro Performance Pallet for secure, repeatable transfers between machines.

- Rough mill cavities and runners on a 5-axis machine using a MaxxMagnum manual chuck to remove bulk material quickly.

- Machine electrodes on a 3-axis electrode center using MaxxMacro multi-chucks or rail chucks for long, automated runs.

- Finish cavities and complex features with EDM while the part is held in a low-profile MaxxMacro chuck for stability.

- Machine the subgate (trim and angle) using a MaxxMacro adapter/angle chuck to achieve the correct gate geometry and surface finish.

Using modular pallets and chucks allows the workpiece or pallet to move from machine to machine without re-fixturing, reducing setup time and preserving alignment tolerances across operations.

Which MaxxMacro product do you recommend for mounting and transferring workpieces?

We recommend the MaxxMacro 70 Stainless Performance Rust Proof Pallet with 6mm Dowels (MM-PA70W006). Machined from a solid piece of 440C stainless steel, this performance pallet is corrosion resistant, dimensionally stable, and designed for multiple machine transfers — you can move the part from milling to EDM to inspection without re-clamping, which saves time and reduces error accumulation.

What setup should I use for rough milling of mold cavities and runners?

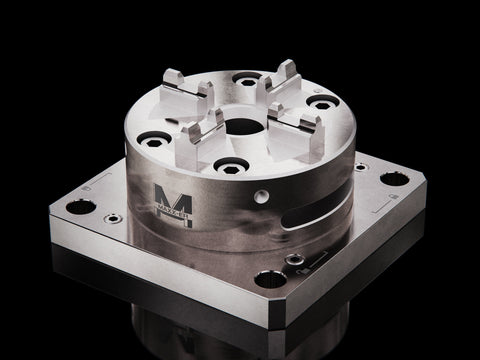

For rough milling on a 5-axis machine we recommend a MaxxMagnum manual chuck such as the MaxxMagnum 680.24RS Manual Chuck Low Profile WEDM Rust Proof (MM-MGMGS000). This chuck supports Macro 54 and Macro 70 fixtures and provides a robust interface for heavy material removal. In roughing you remove bulk material and establish runner geometry so the subsequent EDM burn is faster and focused on finishing critical surfaces and tight tolerances.

How should electrodes be produced for subgate and cavity finishing?

Electrodes are best produced on a dedicated machining center using MaxxMacro multi-chucks or rail chucks to maximize throughput. For long runs use the MaxxMacro 54 Multi 3 Quick Chuck Precision Rail (MM-QCR1S003). For holding round stock for subgate electrodes, the MaxxMacro 54 Stainless ER Collet Chuck ER20 (MM-CC54S020) is an excellent choice. MaxxMacro also offers a wide variety of holders (brass, stainless, aluminum) and pallet options so you can match material and automation needs.

Why use EDM for molding cavities when CNC milling is available?

EDM (Electrical Discharge Machining) is preferred for finishing complex cavity shapes, tight tolerances, and superior surface finish. When cavities are pre-roughed on a 5-axis mill, EDM burn time is reduced and accuracy increases — EDM produces sharp corners, thin ribs, and fine details that are difficult or impossible with conventional milling. Use a low-profile MaxxMacro chuck such as the MaxxMacro 70 Low Profile Manual Chuck with Mounting Plate (MM-MLMPW001) to securely hold the pallet or mounting plate during EDM for the best results.

How do I machine and finish subgates, and which adapter helps set the gate angle?

Subgates require precise orientation and clean trimming to provide the part with optimal cosmetic and functional results while minimizing vestige. Use the MaxxMacro 54 Manual QuickChuck Variable Angle Adapter WEDM Rust Proof (MM-QCVAW001) to set the correct angle for burning or trimming the subgate. The variable-angle adapter gives you the ability to position the electrode or tool at the optimal angle to produce a clean subgate geometry that is easy to deflash and leaves a small vestige.

What are the advantages of using subgates in injection molds?

Subgates (also called submarine gates) are commonly used in injection molding because they combine process and part benefits:

- Improved aesthetics: Subgates leave a small, usually hidden vestige that’s easy to trim and often located in non-visible areas.

- Automatic degating: Parts often separate from the runner automatically during ejection, reducing manual labor.

- Reduced gate marks: The gate location and geometry minimize stress and visible blemishes on the molded part.

- Better flow and pressure control: Subgates allow for precise gate cross-section control which helps balance fill and reduce flow lines and burn marks.

- Shorter cycle times: Proper subgate design can reduce hold/pack times and improve cooling efficiency, especially in multi-cavity tools.

For mold makers, subgates require accurate machining and finish to perform reliably — this is where EDM plus precise MaxxMacro fixturing deliver consistent, repeatable results.

How do MaxxMacro setups improve repeatability and production efficiency?

MaxxMacro systems (pallets, chucks, rail chucks, and adapters) are designed for repeatable interfaces and fast changeovers. Key efficiency points include:

- Single-mount transfer: Mount once on a performance pallet (e.g., MM-PA70W006) and move the pallet between machines without re-clamping.

- Modular compatibility: Standardized Macro 54 / Macro 70 interfaces let you share fixtures across mills, EDMs, and inspection systems.

- Reduced setup time: Quick chucks and rail systems enable batch electrode machining and fast pallet swaps.

- Higher uptime: Durable stainless and rust-proof components reduce maintenance and preserve alignment over many cycles.

Can you summarize recommended MaxxMacro items used in this guide?

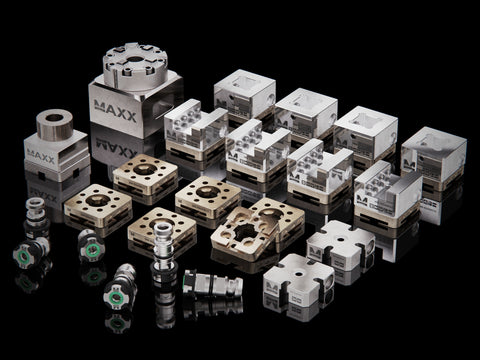

Yes — the key components referenced in this process are:

- MaxxMacro 70 Stainless Performance Rust Proof Pallet (MM-PA70W006) — pallet for transfers

- MaxxMagnum 680.24RS Manual Chuck Low Profile WEDM Rust Proof (MM-MGMGS000) — 5-axis rough milling chuck

- MaxxMacro 54 Multi 3 Quick Chuck Precision Rail (MM-QCR1S003) — electrode rail chuck

- MaxxMacro 54 Stainless ER Collet Chuck ER20 (MM-CC54S020) — round stock electrode holding

- MaxxMacro 70 Low Profile Manual Chuck with Mounting Plate (MM-MLMPW001) — EDM chuck

- MaxxMacro 54 Manual QuickChuck Variable Angle Adapter (MM-QCVAW001) — subgate angle adapter

What best practices should mold makers follow when using subgates with MaxxMacro systems?

Follow these recommendations to maximize success:

- Always use a performance pallet for multi-machine workflows to eliminate repeated fixturing errors.

- Rough cavities first (5-axis) to minimize EDM burn time; then finish with EDM for tolerance and surface quality.

- Standardize electrode holders and chucks so tools and electrodes can be produced in automated batches.

- Validate subgate geometry with a prototype run and inspect the vestige location to ensure cosmetic requirements are met.

- Document and label pallet orientations (dowel pins, datum faces) so operators can swap pallets without ambiguity.

MaxxMacro Premium Pallets. How do they look after 2800 cycles?

Published on: Oct 28, 2020

"In general any visual wear was very minimal and unmeasurable."

Report characteristics provided by Independent source "Dynamic Innovative Mold Building" a BIG thanks to them for allowing Maxx to show them the "Proofs in the pudding" ..my kids would call me a boomer...

- Test assumes the average electrode is cycled into a 3R-carbide chuck 5 times per week (260 times per year)

- Test Cycled one Maxx Tooling 50mm holder 2,844 times capturing offset data every 6th tool change

- Holder reference elements were noted to be out of square by .0005 prior to test, simulating potential worse case scenario

- Reference elements had thin layer of red marker applied prior to test to visually show any wear on bearing surfaces

- Before and after CMM results were taken to compare and verify offset data of the electrode

In general any visual wear was very minimal and unmeasurable

All offset data and CMM Data appear to be within an acceptable range

Assumptions

Test assumes the average electrode is cycled into a 3R-carbide chuck 5 times per week (260 times per year)

Test Cycled one Maxx Tooling 50mm holder 2,844 times capturing offset data every 6th tool change

In general any visual wear was very minimal and unmeasurable

All offset data and CMM Data appear to be within an acceptable range

Reference elements seat using corner like 3R, not on an angled surface

The 2024 SKU Update for Enhanced Clarity and Compatibility

Published on: Nov 8, 2024

At MaxxTooling, we're always looking for ways to improve your experience with our products and services. This year, we introduced a major update to our SKU system, designed to simplify product identification, improve inventory management, and enhance your overall experience. Here’s what this new system brings to the table—and how it benefits you.

What is a SKU? A SKU (Stock Keeping Unit) is a unique identifier used to track a product in inventory and make it easy to identify.

Why Did We Update the SKU System?

As our product family expands, we needed a improved SKU system that would deliver the following benefits:

- Consistency and Clarity: SKUs now follow a single, well-defined rule, making them easier to read and understand.

- Family and Product Matching: Each SKU reflects its product family, allowing you to identify compatible items more easily.

- Support for Future Growth: The new format makes it simple to accommodate new product introductions, family expansions, and variations.

- Integration with Adapter Plates and Custom Products: The revised structure also allows for easier integration of adapter plate codes, optional parts, and other customization options.

- Better ERP and Spreadsheet Integration: Standardized SKUs streamline data entry, making it easier to integrate with ERP systems, spreadsheets, and custom properties.

What Does the New SKU Format Look Like?

Our SKUs now follow a standardized, informative structure:

MX-XXXXMSSS(-O-CODE)

Here’s what each section means:

- Prefix (MX/MM): Identifies MaxxTooling or MaxxMacro as the source, with additional prefixes planned for future products.

- Family Code (XXXX): A four-character code indicating the product family.

- Material Code (M): One character indicating the material.

- Size Code (SSS): Three digits denoting the product’s size or model.

- Optional Code (O): A single character used for optional features, such as performance enhancements, index-disabled features, MXRefix systems, etc.

- Adaptation Code (-CODE): Optional codes for adapter plates, machine-specific modifications, or client custom modifications.

Revision Dates and Compatibility Page

The SKU update process has occurred gradually over the year, with different products receiving updates at different times. Each updated SKU has a specific Revision Date that you can check to ensure compatibility with your needs.

To make this transition easier, we’ve created a dedicated SKU Compatibility Page, where you can:

- Look up compatibility between old and new SKU formats

- Check revision dates for each product

- Access the latest product pages for detailed specifications

Visit the SKUs Compatibility Page

New Laser Markings for Improved Operator Experience

Along with our SKU system update, we’ve also made a significant improvement to the way we laser engrave our products. All of our items now feature new, detailed laser markings that provide essential product information directly on the part. This includes data such as ports, maximum torque values, and other key specifications. These updates make it easier for operators to quickly identify important features, improving workflow efficiency and reducing the chance of errors. The enhanced laser markings are part of our ongoing commitment to making your experience with our products as seamless and efficient as possible.

Our Commitment to Continual Improvement

Updating our SKU system is just the beginning. As we continue expanding and enhancing our product offerings, we’ll keep refining this system to support future growth and product variations. Our goal is to make it as easy as possible for you to select, track, and integrate our products into your workflows.

Thank you for choosing MaxxTooling as your workholding partner. Please explore our SKU Compatibility Page for more information, or feel free to reach out if you have any questions.