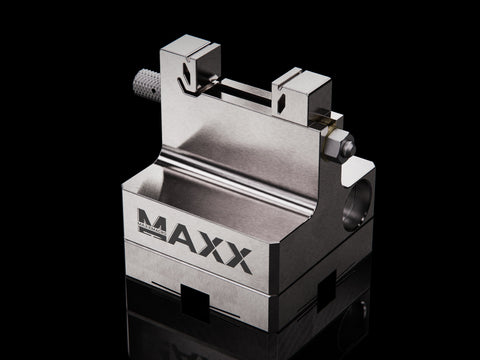

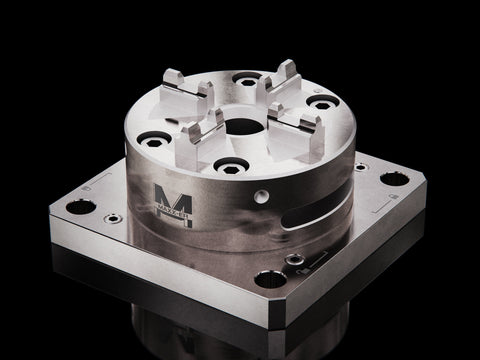

Maxx-ER 50 Stainless ER Collet Chuck ER32C comes fully assembled and ready to use. This product is 100% cross-compatible with the Erowa OEM system. To clamp cylindrical parts with ER Collet System.

MaxxDesign Exclusive Features:

-

High quality materials.

- 100% cross-compatible with OEM system

Product Information:

Maxx-ER 50 ER32 Collet Chuck 8566C is 100% cross compatible with Erowa IT System.

Maxx-ER performance Collet Chucks are precision machined for accuracy and durability ±0.015mm concentricity and .002mm repeatability

Maxx-ER 50 ER32 Collet Chuck 8566C comes with external gripper slots for robotic operations.

All Maxx-ER holders are post assembly ground to ensure the industries best flatness tolerances, Feet are torqued and ground to maximise performance.

Includes Flushing though

Product Specifics

-

Spigot required:

ITS Chucking Spigot

-

Reference Element Included:

[ME-CP50R000]

-

Included Items:

MX-CCRPS032

-

Clamping Range:

ø 2 - 20 mm

-

Accessories:

[MX-CCRPR032]

-

Automation:

er robot gripper c,

-

Repair Kit / Replacements:

[MX-CCRPS032]

Product Details

|

Product Name

|

Maxx-ER 093999 50 Stainless ER Collet Chuck ER32C |

|

SKU

[Old SKU]

|

ME-CC50S132

[MX-ER32C2]

|

|

System

|

Maxx-ER

|

|

Cross-Compatible

|

ER-093999

|

|

System Repeatability

|

0.002mm |

|

Material

|

Stainless 420C

|

Nut: Stainless 420C

|

|

Weight

|

0.998 kg | 2.2 lb

|

Returns Policy

You may return most new, unused items within 30 days of delivery for a refund. There is a 20% restock fee if the item is returned due to customer error. The customer is responsible for the return shipping costs if the return is a result of your error (Not if received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the 'Complete Orders' link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

International shipments it is the customers responsibility to determine if there are any taxes or import duties payable and to make arrangements to clear and pay these fees if applicable.

Published on:

Jun 5, 2025

In machining and milling operations, securing cutting tools or workpieces precisely is crucial for achieving optimal results. One of the most popular tool-holding systems used across industries is the ER collet chuck. But what makes the ER collet chuck so widely adopted, and how can it benefit your machining processes? Let’s break it down.

What is an ER Collet Chuck?

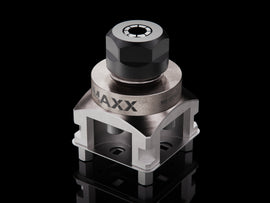

An ER collet chuck consists of three main components: the chuck body, the collet, and the collet nut. The ER collet—a spring collet type—fits into the chuck body, and when the collet nut is tightened, it compresses the collet, gripping the tool or workpiece firmly and concentrically. This secure grip ensures stability and precision during machining.

Key Benefits of ER Collet Chucks

-

High Precision: ER collet chucks deliver exceptional accuracy and minimal runout, enabling tight tolerances and superior finish quality in your workpieces.

-

Versatility: The ER system can hold a wide range of tool diameters. With just one chuck and a set of different collets, you can easily switch between tools without changing the entire chuck, saving both time and money.

-

Strong Grip: The uniform compression of the ER collet ensures a powerful and reliable grip, minimizing slippage even in high-speed machining conditions.

-

Ease of Use: Tool changes are straightforward—just loosen the collet nut, swap the tool, and retighten. This simplicity reduces downtime and boosts productivity on the shop floor.

-

Cost-Effective: Because one chuck can work with many collet sizes, ER collet chucks are an economical solution for diverse machining needs without investing in multiple chucks.

-

Wide Availability: ER collets come in many standard sizes like ER16, ER20, ER25, ER32, and ER40, making it easy to find the perfect fit for your applications.

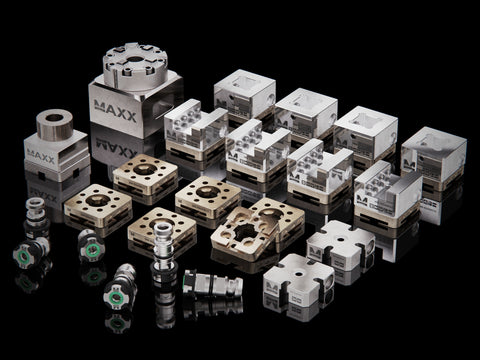

Explore MaxxMacro ER Collet Chucks

For reliable, high-precision ER collet chucks compatible with System 3R macro systems and built for performance, check out our MaxxMacro ER Collet Chuck Collection.

Whether you’re upgrading your toolholding system or starting fresh, MaxxMacro offers a variety of collet chucks engineered to meet your machining demands.

Published on:

Nov 8, 2024

At MaxxTooling, we're always looking for ways to improve your experience with our products and services. This year, we introduced a major update to our SKU system, designed to simplify product identification, improve inventory management, and enhance your overall experience. Here’s what this new system brings to the table—and how it benefits you.

What is a SKU? A SKU (Stock Keeping Unit) is a unique identifier used to track a product in inventory and make it easy to identify.

Why Did We Update the SKU System?

As our product family expands, we needed a improved SKU system that would deliver the following benefits:

-

Consistency and Clarity: SKUs now follow a single, well-defined rule, making them easier to read and understand.

-

Family and Product Matching: Each SKU reflects its product family, allowing you to identify compatible items more easily.

-

Support for Future Growth: The new format makes it simple to accommodate new product introductions, family expansions, and variations.

-

Integration with Adapter Plates and Custom Products: The revised structure also allows for easier integration of adapter plate codes, optional parts, and other customization options.

-

Better ERP and Spreadsheet Integration: Standardized SKUs streamline data entry, making it easier to integrate with ERP systems, spreadsheets, and custom properties.

What Does the New SKU Format Look Like?

Our SKUs now follow a standardized, informative structure:

MX-XXXXMSSS(-O-CODE)

Here’s what each section means:

-

Prefix (MX/MM): Identifies MaxxTooling or MaxxMacro as the source, with additional prefixes planned for future products.

-

Family Code (XXXX): A four-character code indicating the product family.

-

Material Code (M): One character indicating the material.

-

Size Code (SSS): Three digits denoting the product’s size or model.

-

Optional Code (O): A single character used for optional features, such as performance enhancements, index-disabled features, MXRefix systems, etc.

-

Adaptation Code (-CODE): Optional codes for adapter plates, machine-specific modifications, or client custom modifications.

Revision Dates and Compatibility Page

The SKU update process has occurred gradually over the year, with different products receiving updates at different times. Each updated SKU has a specific Revision Date that you can check to ensure compatibility with your needs.

To make this transition easier, we’ve created a dedicated SKU Compatibility Page, where you can:

- Look up compatibility between old and new SKU formats

- Check revision dates for each product

- Access the latest product pages for detailed specifications

Visit the SKUs Compatibility Page

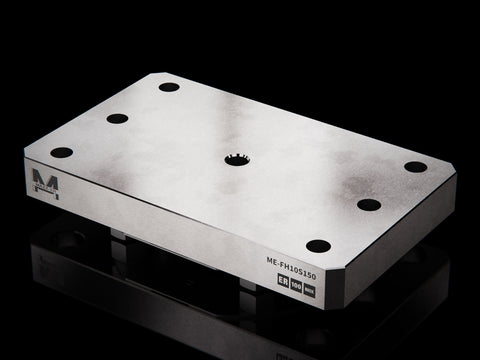

New Laser Markings for Improved Operator Experience

Along with our SKU system update, we’ve also made a significant improvement to the way we laser engrave our products. All of our items now feature new, detailed laser markings that provide essential product information directly on the part. This includes data such as ports, maximum torque values, and other key specifications. These updates make it easier for operators to quickly identify important features, improving workflow efficiency and reducing the chance of errors. The enhanced laser markings are part of our ongoing commitment to making your experience with our products as seamless and efficient as possible.

Our Commitment to Continual Improvement

Updating our SKU system is just the beginning. As we continue expanding and enhancing our product offerings, we’ll keep refining this system to support future growth and product variations. Our goal is to make it as easy as possible for you to select, track, and integrate our products into your workflows.

Thank you for choosing MaxxTooling as your workholding partner. Please explore our SKU Compatibility Page for more information, or feel free to reach out if you have any questions.