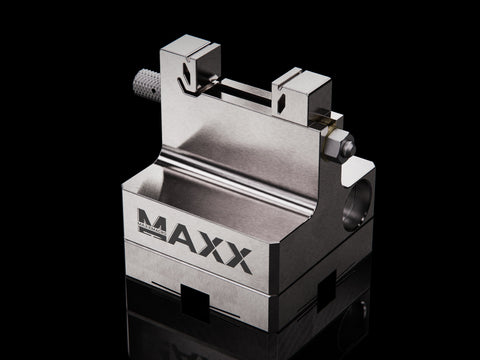

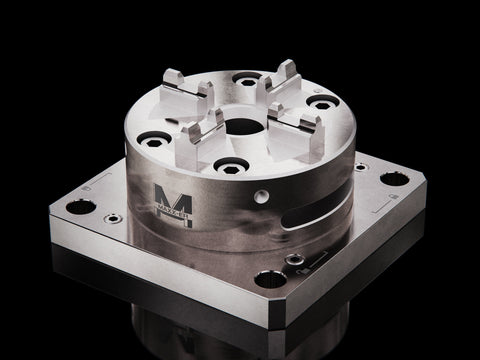

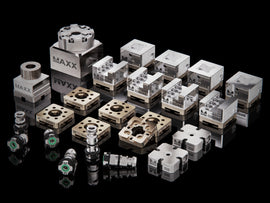

MaxxMacro 4 Sided Tombstone with 8 Manual Low Profile Chuck comes fully assembled and ready to use. This product is 100% cross-compatible with the System 3R Macro OEM system. Tombstone with multiple chucks, ideal for 5th-axis setups.

MaxxDesign Exclusive Features:

- Eight MaxxMacro Low Profile Chucks: Supports MaxxMacro 54 and MaxxMacro 70

- High quality materials: Full corrosion resistant

- Reference surface: For coordinate measurement

- Included thread for eyebolt: M8x1.25

- Flexible mounting holes: both square and radial patterns

Tombstones:

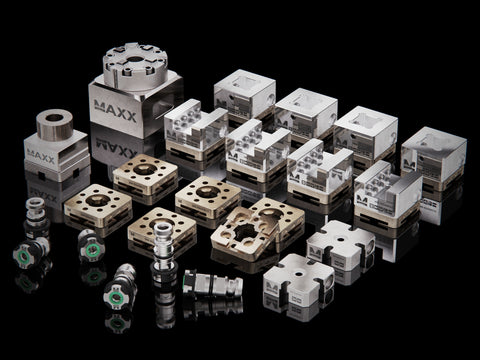

MaxxMacro tombstones offer enhanced machine utilization and extended operational periods through versatile clamping options. Compatible with horizontal machining centers and smaller vertical machines featuring 3, 4 or 5 axis tables, these tombstones cater to diverse machining needs. MaxxMacro tombstones provide a comprehensive solution for milling multiple parts simultaneously, allowing for efficient, unattended machining.

The swift and precise tooling changeovers facilitated by our MaxxMacro clamping system ensure seamless transitions between tasks, whether for extended production runs or shorter cycles. By minimizing downtime and tool changes, they maximize machining hours, enhancing overall productivity. Furthermore, their compact design makes them suitable for integration into smaller 5-axis machine tools, contributing to space efficiency without compromising functionality.

Offering quick setup and dismantling within the MaxxMacro system, tombstones streamline operational processes, saving valuable setup time. Their flexibility extends to a wide range of variations, making them adaptable to any machine tool configuration. Moreover, their user-friendly operation, characterized by a simple and robust mechanical design with minimal components, ensures durability with minimal maintenance requirements.

MaxxMacro tombstones are designed with modularity in mind, allowing for easy system size adjustments and the incorporation of additional components as needed. This modular approach enhances scalability and versatility, catering to evolving machining requirements with ease.

- Enhanced Machine Utilization: MaxxMacro tombstones optimize machine performance by efficiently holding multiple parts simultaneously, maximizing operational efficiency and extending running periods.

- Seamless Tooling Changeovers: Swift and precise tooling changeovers minimize downtime, facilitating smooth transitions between tasks and maximizing overall productivity.

- Quick Setup and Dismantling: MaxxMacro tombstones streamline operational processes with quick and effortless setup and dismantling within the MaxxMacro system, saving valuable setup time and enhancing workflow efficiency.

Product Specifics

- Clamping Type: Manual (6 Nm)

- Clamping Force: 6 kN

-

Drawbar required

:

[MM-DRWBR101]MaxxMacro 605.2RS Short Manual Drawbar Stainless

MaxxMacro 605.2RS Short Manual Drawbar Stainless

Regular price $60.00 AUD -

Chuck Included:

[MM-ML70W000]MaxxMacro 70 Low Profile Manual Chuck 600.28-S WEDM Rust Proof

MaxxMacro 70 Low Profile Manual Chuck 600.28-S WEDM Rust Proof

Regular price $4,601.00 AUD

Product Details

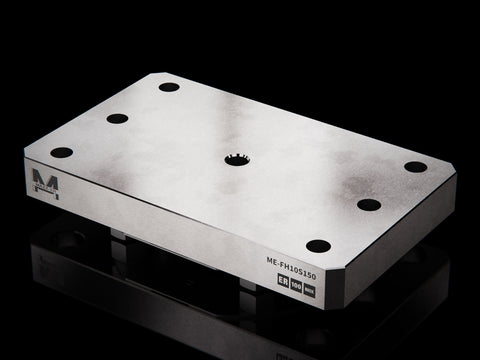

| Product Name | MaxxMacro 4 Sided Tombstone with 8 Manual Low Profile Chuck |

| SKU | MM-TSMLA401 |

| System | MaxxMacro (System 3R 100% Cross-Compatible) |

| System Repeatability | 0.002mm |

| Material | Tombstone: Aluminum |

| Weight | 26.32 kg | 58.03 lb |

Returns Policy

You may return most new, unused items within 30 days of delivery for a refund. There is a 20% restock fee if the item is returned due to customer error. The customer is responsible for the return shipping costs if the return is a result of your error (Not if received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the 'Complete Orders' link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

International shipments it is the customers responsibility to determine if there are any taxes or import duties payable and to make arrangements to clear and pay these fees if applicable.