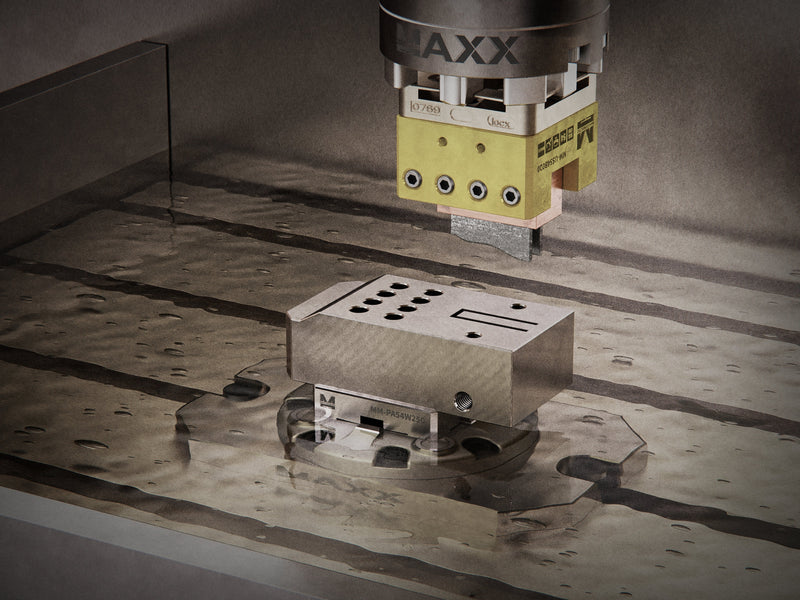

Plastic Injection Mold Production with Subgates: Step-by-Step Using MaxxMacro Workholding Systems

What is the typical workflow to produce an injection mold with subgates using MaxxMacro setups?

The typical workflow follows sequential stages that combine CNC machining and EDM with modular Maxx...

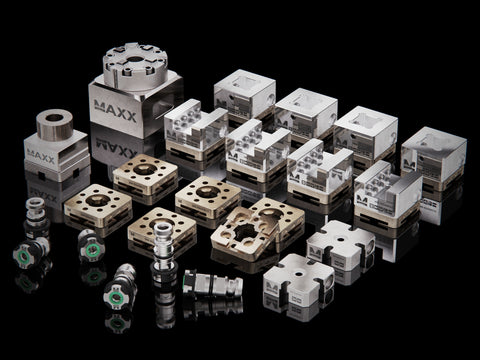

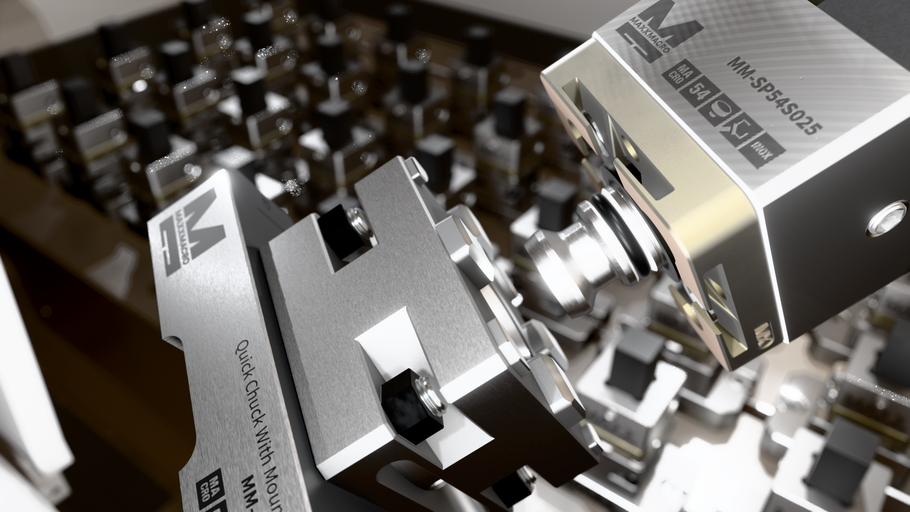

MaxxMacro Products for EDM: Spindles, Pallets, and Electrode Holders

⚡ EDM is easier with MaxxMacro! From the MaxxMacro Spindle Chuck 🛠️ and Table Chuck 🛠️, to Performance Pallets 📦 for holding your workpiece, and Holders ⚡ for your electrodes — we’ve got you covere...

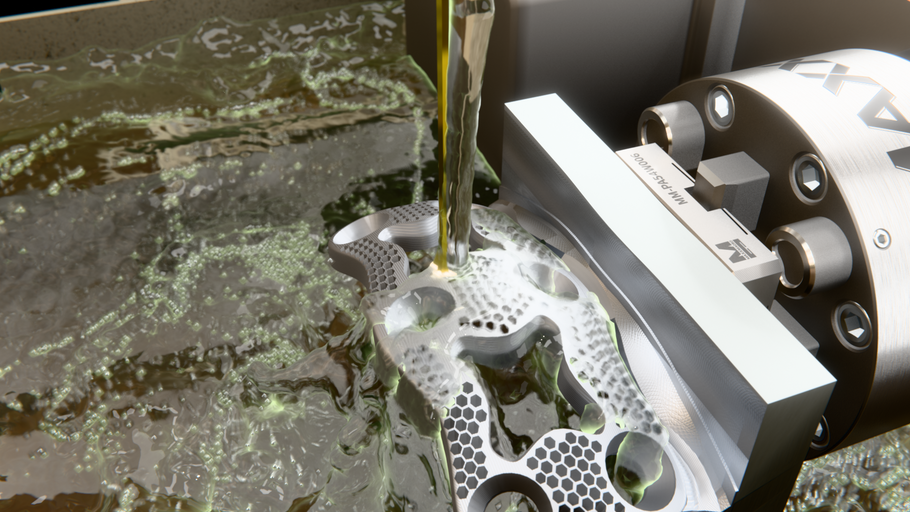

Customer Spotlight: Indy Honeycomb & Our 10,000th Order 🎉

At MaxxTooling, every order matters — but this one was extra special. We recently reached an incredible milestone: 10,000 orders shipped! And the honor of placing this landmark order went to Indy H...

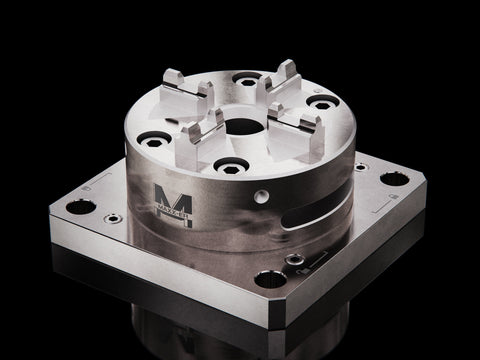

Producing a High-Precision Medical Part with MaxxMacro: A Step-by-Step Setup Breakdown

Watch how MaxxMacro can streamline your production—from 5-axis machining to CMM inspection and even EDM hole popping. When you set up MaxxMacro chucks on your machines, no further alignment is need...

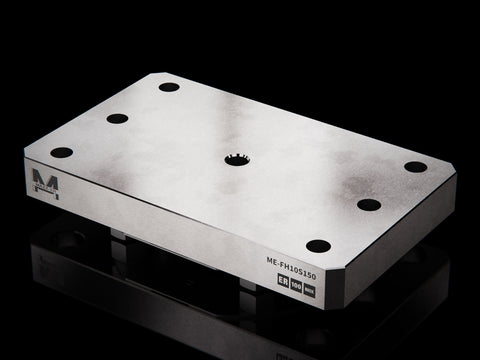

Understanding ER Collet Chucks: Precision, Versatility, and Reliability in Machining

In machining and milling operations, securing cutting tools or workpieces precisely is crucial for achieving optimal results. One of the most popular tool-holding systems used across industries is ...

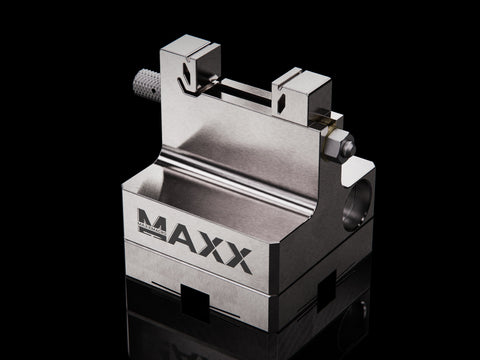

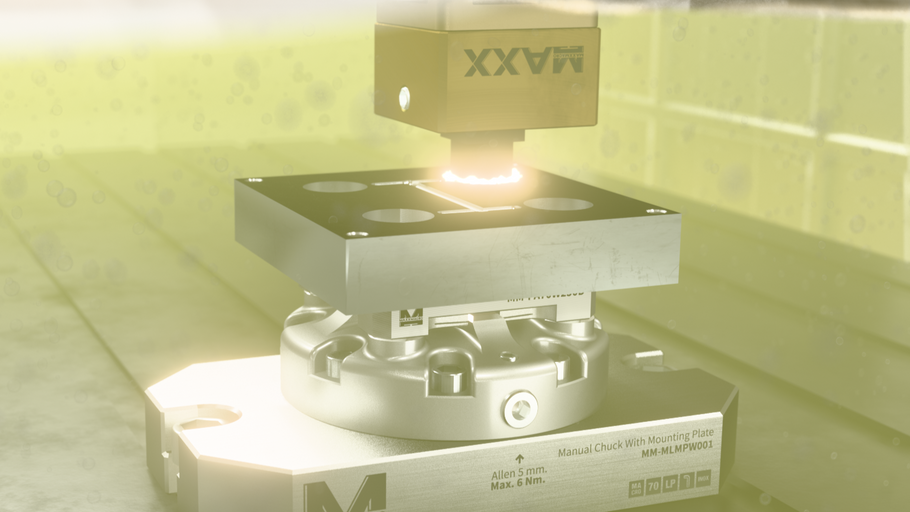

MaxxMacro® Essentials: How Drawbar, Pallet & Chuck Work Together

Are you new to workholding systems or looking to better understand how the MaxxMacro® system operates? In this video, we break down the core components—drawbar, pallet, and chuck—and explain how th...