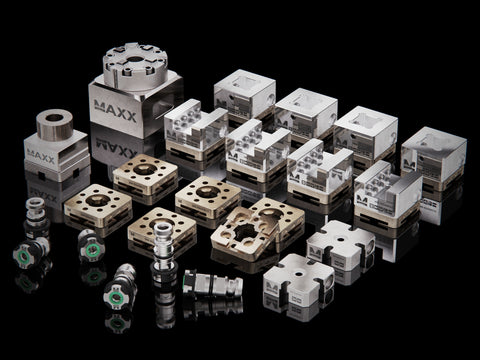

Watch how MaxxMacro can streamline your production—from 5-axis machining to CMM inspection and even EDM hole popping. When you set up MaxxMacro chucks on your machines, no further alignment is needed. Jump from machine to machine without losing valuable setup time.

Let’s break down the video and walk through each step of the process. Every setup uses MaxxMacro components, highlighting our most cost-effective and high-precision workholding solutions.

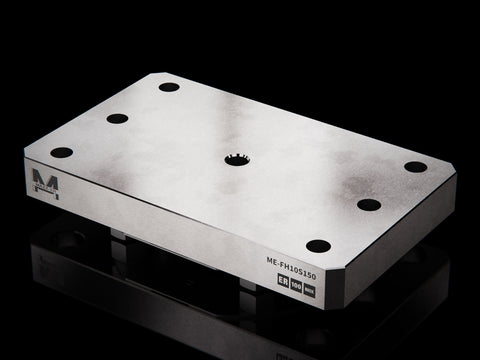

Quick Preparation for MaxxMacro Performance Pallet

With just four threaded holes, you're ready to mount the MaxxMacro Performance Pallet to your workpiece. It’s fast, repeatable, and sets the foundation for your entire setup. This is the simplest way to add any workpiece or fixture to the system. Dowels can be added if needed.

Of course, we also offer a wide range of vises and holders, but the pallet system alone is a powerful option. You can choose between a MaxxMacro 54 or MaxxMacro 70 Performance Pallet, with dowels available in metric or imperial sizes to match your setup.

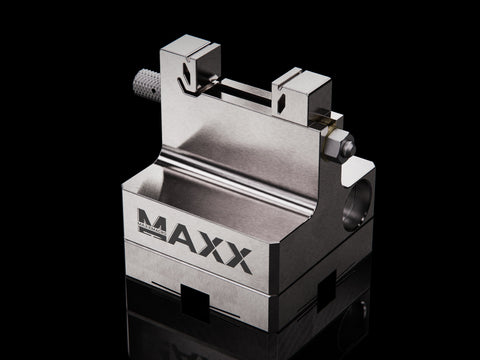

5-Axis Machining with MaxxMagnum Manual Chuck

For 5-axis machining, our MaxxMagnum Low Profile Manual Chuck 68024V offers unmatched adaptability. It includes an adapter plate that allows easy mounting on most machine tables and enables you to fully leverage 5-axis capabilities—ideal for working on complex, multi-angle parts.

A MaxxMagnum chuck also lets you seamlessly switch between MaxxMacro 54, MaxxMacro 70, and MaxxMagnum interfaces, giving you the flexibility to choose the fixture that best suits your part geometry or machining strategy. Whether you're running short batches or long production cycles, this chuck helps you minimize setup time and maintain part consistency across shifts.

CMM Inspection with MaxxMacro 70 Manual Chuck

Inspection is just as critical as machining—and the MaxxMacro 70 Low Profile Manual Chuck (60028) ensures your parts are held securely and precisely during metrology. Mounted with a versatile adapter plate, this chuck can be installed on a wide range of machine tables.

Thanks to its low-profile design, it maximizes your machine’s effective height, allowing you to inspect taller parts without obstruction or additional adjustment. With a repeatability of 0.002 mm, it brings exceptional accuracy and reliability to your CMM operations.

Easily Switch Drawbars Based on Chuck Installed

Our interchangeable drawbars make it easy to adapt to the chuck you’re using. Simply refer to the product page of the chuck you’re using to confirm the right drawbar model. If it doesn’t match, just rotate, remove, and replace—it’s a quick change that keeps your operation moving without interruption.

EDM Hole Popping with B-Axis MaxxMacro Pneumatic Chuck

The MaxxMacro 70 Pneumatic Chuck 6001430 can be mounted directly on the machine spindle, a B-axis, or a fixed fixture. It’s easy to actuate and ideal for a wide range of applications. Like most MaxxMacro pneumatic chucks, it includes an air-clean Z-pad function to ensure debris-free operation.

This chuck supports both Macro 54 and Macro 70 fixtures, giving you flexibility in how you set up your processes. In this case, it's used for EDM hole popping, ensuring the cleanest and most precise process every time.

Laser Marking with MaxxMacro 90° Adapter

If your application requires angled access—whether for laser engraving or another specialized process—you’ll need to have your part precisely positioned. That’s where our MaxxMacro angle adapters come in.

We offer a variety of angle solutions, including the 90° MaxxMacro Adapter, to help you orient your part correctly. These adapters ensure that every mark, cut, or feature lands exactly where it should. They're a smart addition to your tooling setup and will save you time and headaches across multiple jobs.

Check out our full adapter selection here.

Wire EDM Setup with MaxxMacro 54 QuickChuck

The MaxxMacro 54 Manual QuickChuck paired with a horizontal RSM mounting plate, features built-in alignment guides to precisely position the chuck—making it a reliable choice for high-precision Wire EDM setups. It positions the workpiece just above the zero line for optimal cutting and is fully rust-proof to ensure long-lasting durability in wire EDM environments.

📽️ Check our Youtube Channel